- Ev

- >

- Ürünler

- >

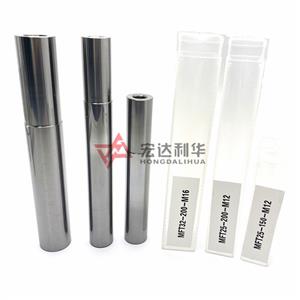

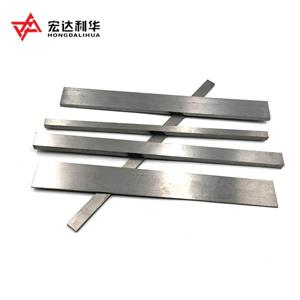

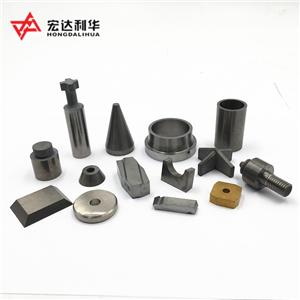

- Tungsten Carbide Customized Cutters

- >

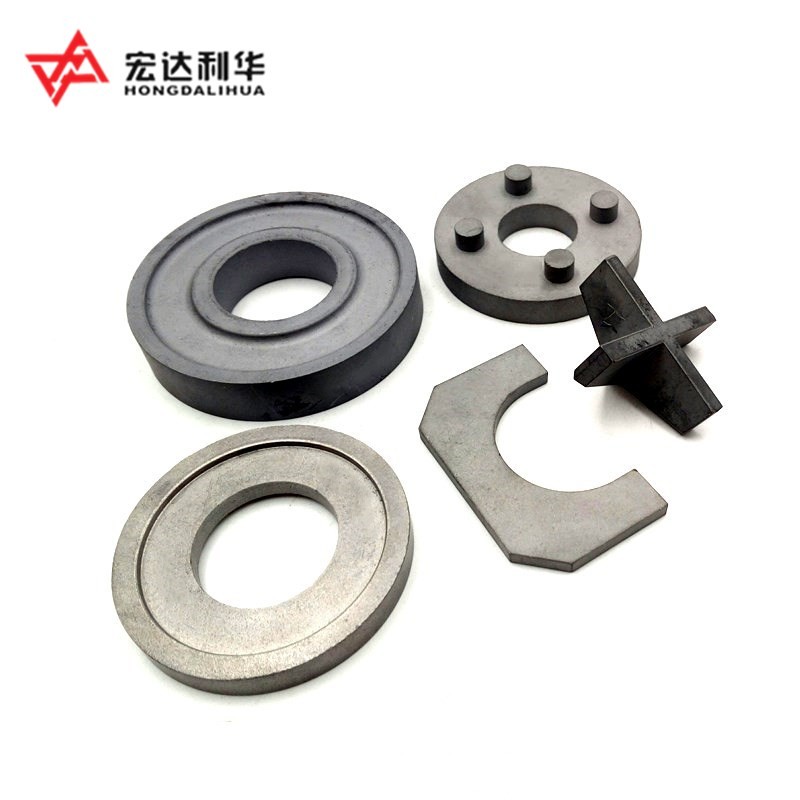

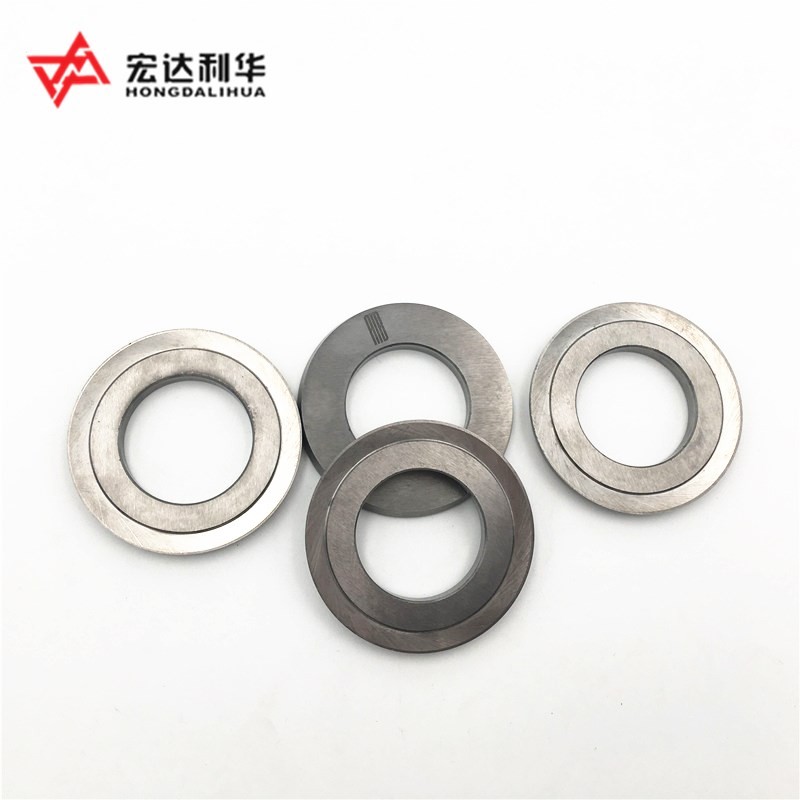

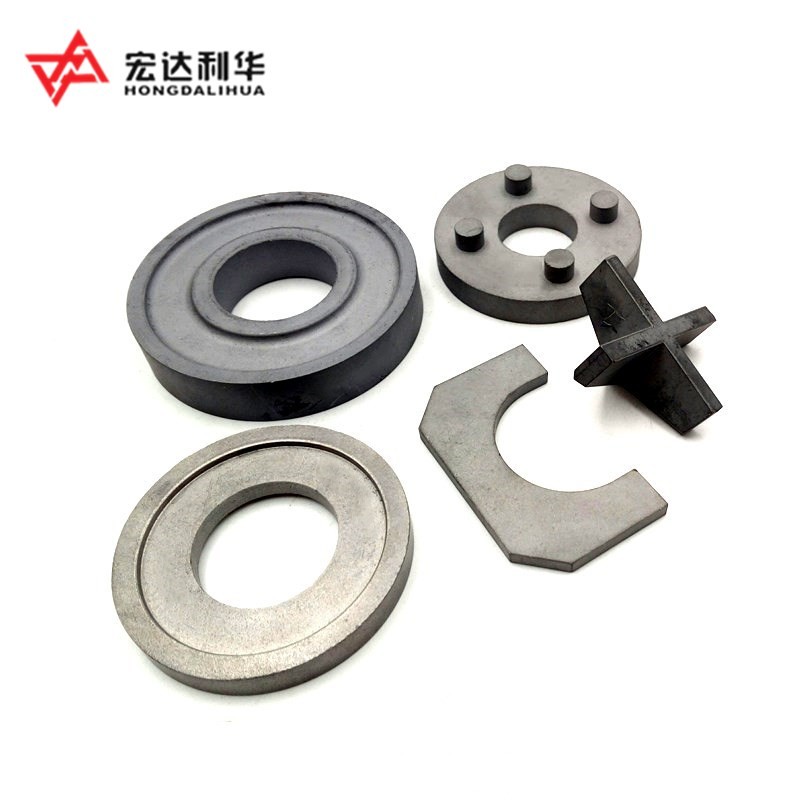

- China Factory Supplier Wholesale Customized Solid Carbide Spare Parts

China Factory Supplier Wholesale Customized Solid Carbide Spare Parts

Marka :Lihua

Ürünün menşei :Zhuzhou, China

Teslimat süresi :7-15 Working Days

arz kapasitesi :50000 Prices per Month

K01

15,1-15,4

≥1300

≥91.5

YG6X

K10 | 14,8-15,1≥1560 | ≥91.0 | Soğutulmuş dökme demir, alaşımlı dökme demir, refrakter çelik ve alaşımlı çeliklerin işlenmesi için uygundur. Ortak dökme demirin işlenmesi için de uygundur. | YG6A |

K10 | 14,7-15,1 | ≥1580 | ≥91.0 | YG6 |

K20 | 14,7-15,1 | ≥1670 | ≥89.5 | Dökme demir, demir dışı metal, alaşım ve alaşımsız malzemeler için finiş işleme ve yarı finiş işleme için uygundur. Ayrıca çelik ve demir dışı metal için tel çekme, jeoloji kullanımı için elektrikli matkap ve çelik matkap vb. |

YG8 | K20-K30 | 14,6-14,9 | ≥1840 | ≥89 |

Refrakter çeliğin, yüksek manganlı çeliğin ve ortak çeliğin yarı finiş işleme için nitelikli. | 14.45 | 2800 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

YG15 | 14.10 | 2400 | 86.5 | Used for punch dies,stamping dies and wear resistance parts |

Grade | Equal to ISO Category Number | Performance |

Application | ||

Density | Bend Strength | Hardness | |||

G/Cm3 | N/mm2 | HRA | |||

YG3 | K01 | 14.9-15.3 | ≥1180 | ≥90.5 | sand-blasting nozzlesQualified for fine turning and half-fine turning when cast iron, non-ferrous metal, alloys as well as non-alloy materials cutting consecutively. Can make wire drawing of steel and non-ferrous metal. Also qualified for sand-blasting nozzles. |

YG3X | K01 | 15.1-15.4 | ≥1300 | ≥91.5 | |

YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | |

YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

YG8 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

YT15 | P10 | 11.1-11.6 | ≥1180 | ≥91.0 | Qualified for rough machining, semi-finish machining and finish machining during consecutive machining of carbon steel and alloy steel. |

YT14 | P20 | 11.2-11.8 | ≥1270 | ≥90.5 | Qualified for rough machining for rough face of carbon steel and alloy steel, half process during discontinuity cutting. |

YT5 | P30 | 12.5-13.2 | ≥1430 | ≥89.5 | Qualified for rough machining for rough face of carbon steel and alloy steel and discontinuity cutting. |

YW1 | M10 | 12.7-13.5 | ≥1180 | ≥91.5 | Qualified for finishing and semi-finishing machining of refractory steel, high manganese steel and common steel. |

YW2 | M20 | 12.5-13.2 | ≥1350 | ≥90.5 | Qualified for semi-finishing machining of refractory steel, high manganese steel and common steel. |